Know About

Calcium Carbonate In Polymer

We'll do everything in our power to satisfy our customers

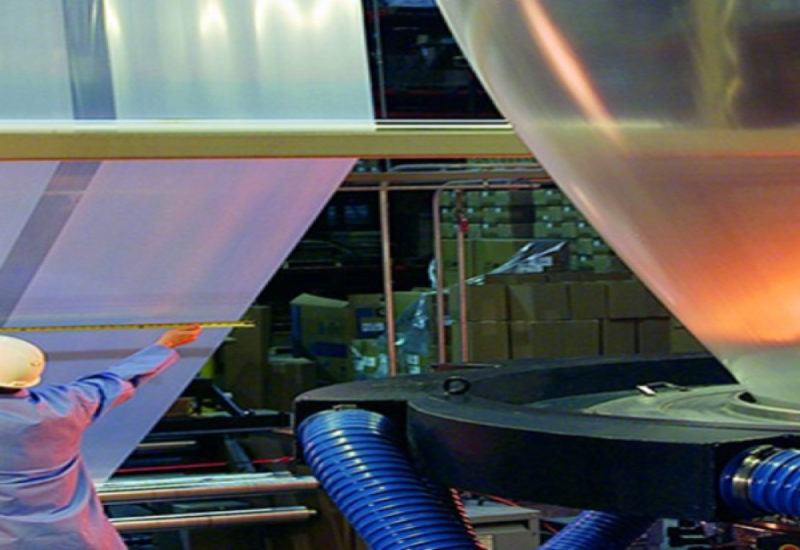

Film

Our Calcium Carbonate with reduced top cut, high purity and excellent coating properties is used to enhance the mechanical properties and improve productivity in a wide range of applications from thin films to thicker sheets i.e. improve impact strength, tear propagation and higher stiffness.

The main benefits are:

01- Increased specific output

- Faster heating and cooling

- Down-gauging option

- Improved toughness

Sheet

ACC grades significantly improve stiffness of polypropylene and polystyrene allowing for substantial reduction in sheet gauge thus leading to optimized formulation costs.

The main benefits are:

02- Higher extruder output in sheet extrusion and thermoforming

- Reduced cooling time in mold and faster cycles

- Higher stiffness

- Lower Shrinkage

- Improving forming accuracy

Woven Tape

ACC grades of fine-ground and treated Calcium Carbonates, provide superior mechanical properties and improved economics for the tape production for raffia bags. ACC Calcium Carbonates are used in PE and PP woven bags, weaving tapes to offer anti-splitting . The grades purity provide high UV-stability.

Special grades allow higher addition levels. The right coating and the unique particle size distribution of ACC special grades are optimized to achieve high mineral levels in polyolefin masterbatches.

The main benefits are:

03- Increased Stiffness

- Improved economics

Nonwoven Fabric

ACC developed mineral modifier for the polyester nonwoven intended for disposable and durable applications. This super mineral modifier can be utilized to reduce raw material costs and improve the quality of nonwoven fabrics and fibers.

The main benefits are:

04- Cost reduction

- Soft touch

- Improved adhesion

- Higher opacity

- Antilocking effect

Blow Molding

ACC grades improves the cycle time, stiffness and impact resistance in injection molding and blow molding applications.

The higher thermal conductivity and lower specific heat of our grades are key advantage in the molding application.

The main benefits of blow molding:

05- Reduced cycle time

- Sustained top load and drop impact at reduced gauge

- Increase stiffness and environmental stress cracking resistance (ESCR) which allows to reduce wall thickness of blow molded articles and save material costs

Pipe and Profile

ACC Calcium Carbonate grades are used in rigid PVC and PO pipes applications.

Our range of coated products offers an excellent dispersion in the polymer matrix and allows high mineral loading percentages. This will achieve a substantial material cost saving.

The main benefits are:

06- Improved processing – reduced cooling time

- Higher ring stiffness

- Mechanical requirements for PVC pressure pipes

- Reduce cycle time – fittings

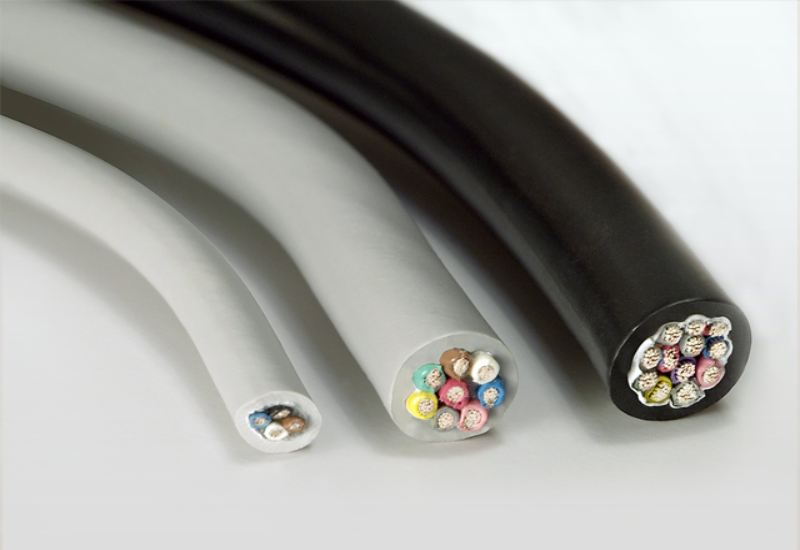

Cable

Our grades are the preferred minerals in plasticized PVC cable application to significantly reduce formulation costs.

In addition to cost savings, several properties can be enhanced:

07- Better electrical properties

- Higher gloss

- Better printability

- Lower plasticizer and stabilizer absorption and better dispersion with our treated grades

- Improved volume resistivity

High Standards Of Our Products

To ensure the high standards of our products we strictly follow the international guidelines